Production Description

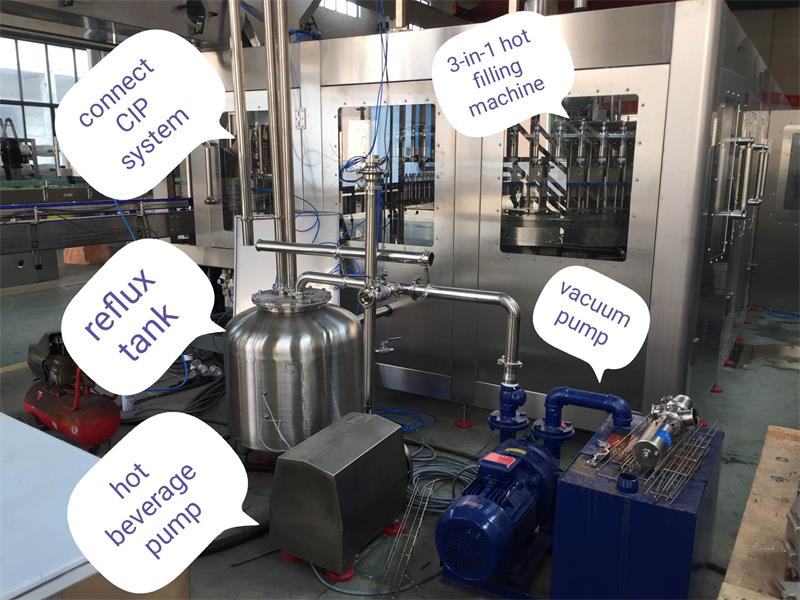

1. Washing Part: ● Except the down framework, the transmission parts and some parts that must be made of special materials. Other parts are all made of stainless steel 304. ● The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE. ● The gripper is made of stainless steel, the position where hold the bottleneck is made of food standard rubber; ● Rinsing time can be guaranteed for 4 seconds.

Technical Parameters

| Project Name:Fruit Juice Hot Filling Machine | ||||||

| Model | RXGF 14-12-5 | RXGF 16-16-5 | RXGF 24-24-8 | RXGF 32-32-8 | RXGF 40-40-10 | RXGF 50-50-12 |

| Washing Nos | 14 | 16 | 24 | 32 | 40 | 50 |

| Filling Nos | 12 | 16 | 24 | 32 | 40 | 50 |

| Capping Nos | 5 | 5 | 8 | 8 | 10 | 12 |

| Capacity(BPH) | 3500 | 5000 | 8000 | 12000 | 15000 | 18000 |

| Suitable bottle | Glass bottle and PET bottle | |||||

| Bottle Volume | 150ml to 2.5Ltr (Customized) | |||||

| Bottle diameter(mm) | Dia50-Dia115 | |||||

| Bottle height | 160-320mm | |||||

| Compress air pressure(Mpa) | 0.3-0.4 | |||||

| Washing medium | Aspetic water | |||||

| Rinsing pressure(Mpa) | >0.06 <0.2 | |||||

| Filling temperature (℃) | 85~90℃ | |||||

| Filling theory | Micro negative pressure filling | |||||

| Application | Fruit juice hot filling machine | |||||

| Total powder | 2KW | 2.2KW | 3KW | 4KW | 7.5KW | 7.5KW |

| Measurement (mm) | 2360*1770*2700 | 2760*2060*2700 | 2800*2330*2700 | 4215*2960*2700 | 4360*3300*2700 | 5900*3300*2700 |

| Weight | 3200kg | 4000kg | 4500kg | 6500kg | 8000kg | 9500kg |

Configuration List

| No | Name | Brand |

| 1 | Main motor | ABB |

| 2 | Cap unscrambler motor | FEITUO(China) |

| 3 | Conveyor motor | FEITUO(China) |

| 4 | Rinsing pump | CNP (China) |

| 5 | Solenoid valve | FESTO |

| 6 | Cylinder | FESTO |

| 7 | Air-T contactor | FESTO |

| 8 | Pressure adjust valve | FESTO |

| 9 | Inverter | MITSUBISHI |

| 10 | Power switch | MIWE(TAIWAN) |

| 11 | Contactor | SIEMENS |

| 12 | Relay | MITSUBISHI |

| 13 | Transformer | MIWE(TAIWAN) |

| 14 | Approx switch | TURCK |

| 17 | PLC | MITSUBISHI |

| 18 | Touch screen | Pro-face |

| 19 | Air components | FESTO |

| 20 | AC Contactor | Schneider |

| 21 | Micro relay | MITSUBISHI |

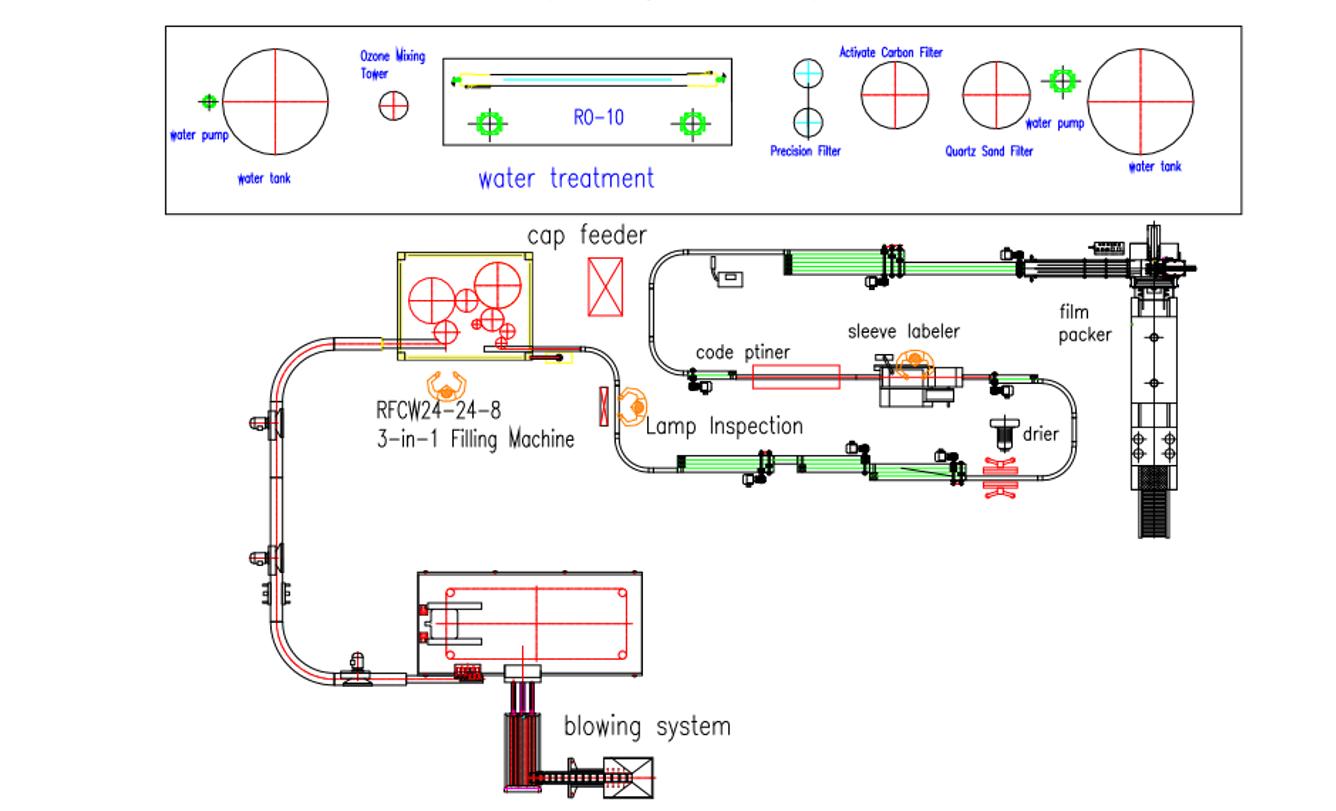

A to Z layout

Why Choose Us