Main Features

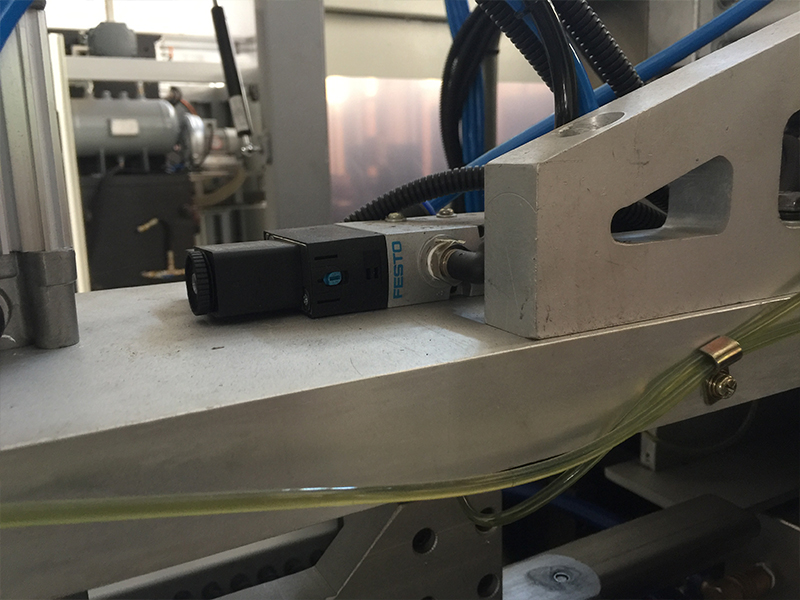

● Man-machine Interface control, easy to operate

● Automatic preform loading and unscrambling

● Preform hopper

● Stable preform alignment, loading preforms according to capacity

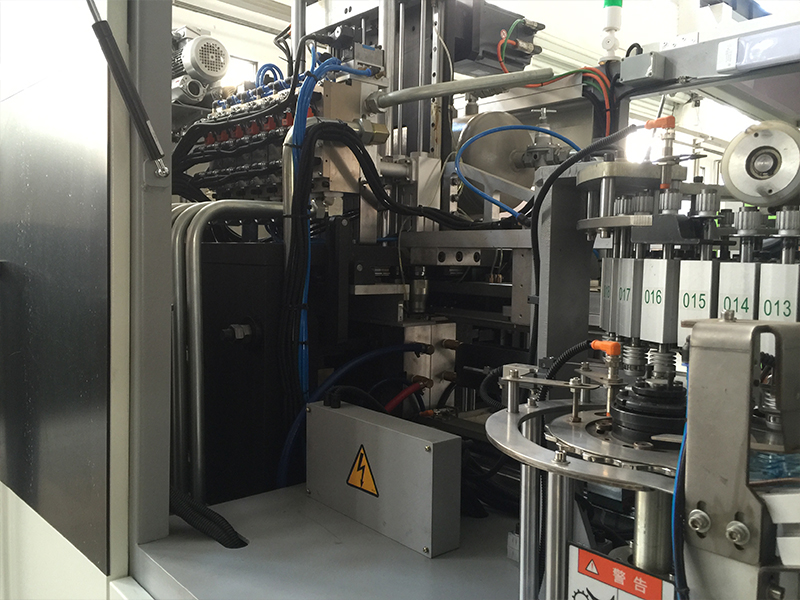

● Close structure, low contamination

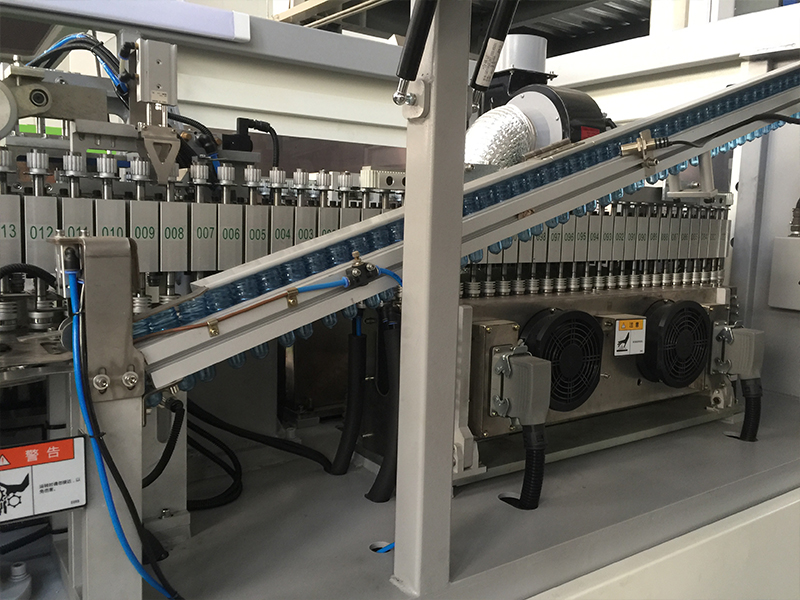

● Well preform heating system

● Stable rotating system

● Preforms are evenly heated, and easy to blow

● Low energy consumption, heating capacity is adjustable

● Recycling air cooling system in oven (option)

● Heating system is a mutual feedback and closed loop system, can works in a constant power output, without being affected by voltage fluctuation.

Product Display

Preform Loading, Bottle Fetching And Outputting

All the preform loading and bottle fetching and out putting movements are finished by mechanical transfer arms, which avoid contamination.Change Moulds

The whole moulds changing takes only one hour.Highautomation, Low Contamination

The whole moulds changing takes only one hour.Product Display

Human-machine Interface And Easy Maintenance

Technical Parameters

| Model | SPB-4000S | SPB-6000S | SPB-8000S | SPB-10000S |

| Cavity | 4 | 6 | 8 |

|

| Output(BPH) 500ML | 6,000 pcs | 12,000 pcs | 16,000 pcs | 18000pcs |

| Bottle size range | Up to 1.5 L | |||

| Air consumption | 6 cube | 8 cube | 10 cube | 12 |

| Blowing pressure | 3.5-4.0Mpa | |||

| Dimensions (mm) | 3280×1750×2200 | 4000 x 2150 x 2500 | 5280×2150×2800 | 5690 x 2250 x 3200 |

| Weight | 5000kg | 6500kg | 10000kg | 13000kg |