| Model | OPP-100 | OPP-200 | OPP-300 | OPP-400 |

| Speed of labeling | 6000BPH | 8000BPH-12000BPH | 15000BPH-18000BPH | 20000BPH-24000BPH |

| Power | AC 3ψ380V50Hz | |||

| Efficiency | ≥99.5 | ≥99.5 | ≥99.5 | ≥99.5 |

| Accuracy of labeling | ±1mm | ±1mm | ±1mm | ±1mm |

| Diameter of bottle | 40-110mm | 40-100mm | 40-100mm | 40-100mm |

| Material of bottle | Glass, Metal, Plastic | Glass, Metal, Plastic | Glass, Metal, Plastic | Glass, Metal, Plastic |

| Shape | Round | Round | Round | Round |

| Label material | OPP,BOPP,PAPER | OPP,BOPP,PAPER | OPP,BOPP,PAPER | OPP,BOPP,PAPER |

| Label thickness | 0.035-0.05mm | 0.035-0.05mm | 0.035-0.05mm | 0.035-0.05mm |

| Label height | 40mm-180mm | 40mm-150mm | 40mm-180mm | 40mm-150mm |

| Inside diameter of paper tube | 6inch | 6inch | 6inch | 6inch |

| Air source | 0.5Mpa | 0.5Mpa | 0.5Mpa | 0.5Mpa |

| Rated power | 10KW | 10KW | 12kw | 12kw |

| Machine size | 3176L*1500W*2050H(mm) | 5000L*1600W*2000H(mm) | ||

| Weight | 2000kg | 2500kg | 3200kg | 3500kg |

| Fully enclosed Host | Door stop |

| send bottles | Screw or star wheel |

| Feeding bottle | cylinder |

| Separate bottle | Stars Wheel |

| Sending label | servo encoder control |

| Illumination | LED, top + bottom access operation lamp lights + electrical control box overhaul lights |

| Fixed feeding shelf | Removable standard planar fast. (Optional double frame) |

| Touch screen | single touch |

| Cabinet work | Column cabinet manually unscrew the formula |

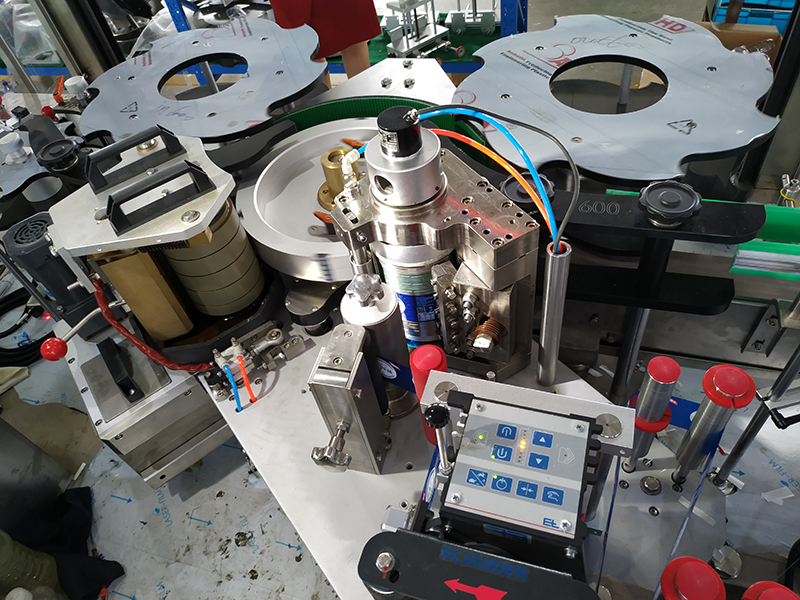

| Corrective devices | Germany E + L |

| Alarm system | warning light & buzzer, lack of material, marked off, open the door |

| Label system | Physical adjustable friction brake feed |

| Transmission systems | machine connections, independent label transmission |