Introduction

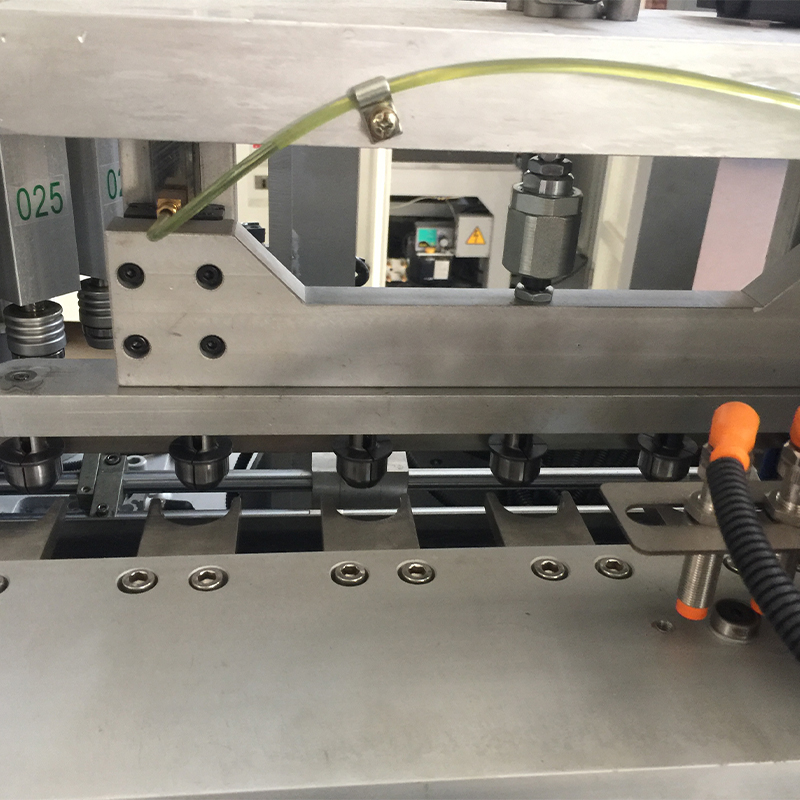

1. Energy saving. 2. Easy to operate, just need feeding preform, other work is automatic. 3. Suitable for hot filling, PP, PET bottle blowing. 4. Suitable for different preform neck size, it can change preform jigs very easily. 5. Mold replacement very easily. 6. Oven design in reasonable, adopt blowing-type, water cooling, air cooling all have. Suitable for hot environment to work, the preform neck can’t distortion. 7. The heating lamp adopt infrared quartz lamp, not easy to damager, it is different than semi-auto blowing machine lamp. So it no needs frequently to change lamp. The lamp life is long, even it is broken, it can use also. 8. Our hand feeding stretch blow molding machine can add autoloader+manipulator to became fully automatic. 9. Our machine is more safety and stabilization. 10. Our clamping unit adopts clooked arm configuration self-lubricating system. So very stabilization and no noise.Technical Parameters

| Model | BL-Z2 | BL-Z4S | BL-Z6S | BL-Z8S |

| Cavities | 2 | 4 | 6 | 8 |

| Capacity(BPH) | 2000 | 4000 | 6000 | 8000 |

| Bottle volume | 100ml-2L(customized) | |||

| Body Diameter | <100mm | |||

| Max Bottle Height | <310mm | |||

| Powder | 25KW | 49KW | 73KW | 85KW |

| Hp air compressor | 2.0m³/min | 4m³/min | 6m³/min | 8m³/min |

| LP air compressor | 1.0m³/min | 1.6m³/min | 2.0m³/min | 2.0m³/min |

| Weight | 2000kg | 3600kg | 3800kg | 4500kg |

Product Display