Production Description

1. Rinser Part: ● All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & more clean. ● 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing. ● 304 stainless steel washing pumps.2. Filler Station: ● High precision filling nozzle, PLC variable signal control, ensure high filling precision. ● Gravity filling, & filling smoothly & steadily. ● All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean. ● No bottle no filling.3. Capper station: ● Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping. ● All 304 stainless steel construction. ● No bottle no capping and Automatic stop when lack of bottle.Product Feature

Product Parameter

1) The machine has compact structure, perfect control system, convenient operation and high automation . 2)Parts in contact with materials are made of imported high quality stainless steel, no process dead Angle, easy to clean. 3)High precision, high speed quantitative filling valve, accurate liquid level without liquid loss, to ensure excellent filling quality. 4) The capping head adopts constant torque device to ensure the capping quality. 5) Adopt efficient capping management system, with perfect cap loading technology and protection device. 6) It is not necessary to adjust the height of the equipment to change the bottle size. It can be realized by replacing the star wheel of the bottle, which is simple and convenient to operate. 7) The filling system adopts the bottle - bottling technology to avoid the secondary pollution of the bottle mouth. 8) The control system has the functions of automatic water level control, missing cap detection, automatic stop of bottle flushing and output counting. 9) The bottle washing system adopts the efficient cleaning spray nozzle produced by American spray Company technology, which can be cleaned to every place in the bottle. 10) The main electrical components, electronic control valves, frequency converters and so on are imported parts to ensure the excellent performance of the whole machine. 11) All components of pneumatic system adopt international famous products. This machine integrated three function: 1. Rinse the empty pet bottle, 2. filling the rinsed bottles, 3. capping the filled bottles. | (1) Direct connection technology between the air conveyor and the bottle feeding dial wheel is adopted, which eliminates the bottle feeding screw and conveying chain, making it easy to change the bottle type. After the bottle enters the machine through the air conveyor, it is directly sent to the bottle rinser by the bottle feeding steel dial wheel (clip bottleneck way). (2) Before the bottle is equipped with automatic bottle stopper. The main function is stop without bottle, start with bottle (to prevent invalid operation and effective energy saving and to prevent bottle jam bottle.) |

| The dish-shaped cylinder is designed to be easy to clean, high-precision, high-speed filling valve, the liquid level is accurate and no liquid loss, ensuring excellent filling quality; when there is no bottle, the valve will not be opened, so that the liquid will not be lost, ensuring excellent filling quality; The filling valve is made of high-quality stainless steel, and the sealing adopts the conical surface method, which is easy to clean and has no scaling. After the bottle mouth contacts the filling valve, it opens to complete the filling process. The filling valve is equipped with a flow control mechanism, and the flow rate can be set within a certain range according to actual needs. The filling and sealing gasket is made of EDPN material, which is resistant to acid, alkali and ozone. Filling with vacuum and excess material function (this function is compatible with CIP) |

| After the bottle enters the host machine, it enters the bottle rinser through the transmission star wheel, and the bottle clamp clamps the bottle mouth and turns up 180° along the bottle flushing guide, so that the bottle mouth is downward. In a specific area of the rinser (determined by the water distribution plate - the rinse water is pumped into the water distribution plate by the rinse water pump, and then distributed to the rinse clamp by the water distribution plate through 24 pipelines), the rinse clamp nozzle is sprayed out Rinse the bottle with water to rinse the inside of the bottle. After being rinsed and drained, the bottle is turned down 180° along the guide rail under the clamping of the bottle clamp, so that the bottle mouth is upward. The washed bottles are led out from the rinser through the transition steel dial (pure water rinse) and sent to the next process - filling. |

| The capping head adopts a magnetic constant torque device. When the capping head takes the cap through the capping tray, the top cover will hold the cap and straighten the cap to ensure the correct position of the cap in the capping mold and ensure the quality of capping. When the capping is completed, the capping head slips against the magnetic force and will not damage the cap, and the capping rod pushes the cap out of the capping mold when the capping head rises. |

| There is a mechanical lifting device for filling. The sliding sleeve roller is lifted and lowered under the action of stainless steel cam. The roller is made of MC oil nylon material, and the service life can reach 5-7 years. |

| Independent 304 stainless steel electrical cabinet.Electrical configuration: PLC:Mitsubishi/Siemens. Inverter: Mitsubishi/Siemens. Touch screen: Mitsubishi/Siemens/Weinview. Contactor:Schneider. Photoelectric:Omron. Proximity switch:Omron. Main motor: ABB. |

| This cap grabber system cancels the taking cap method, which greatly improves the qualified rate of grabbing cap. The capping disc transmits power to the capping head through the pin wheel to ensure that its movement is synchronized with the capping machine. The cap enters the capping disc through the capping channel, and then the cap transfer star wheel transfers the caps to the capping head separately according to the station. At the cap, when the capping head, the center of the capping, and the center of the capping are in a line, the capping film is used to grasp the cap under the action of the capping machine cam. The pass rate of this method for grasping the cap is 100%. |

| Automatic refueling system: Brand Jianhe. The system is controlled by PLC, and the automatic refueling time and cycle can be set on the touch screen to achieve automatic refueling and maintenance during production, which greatly saves labor costs. Oil: No. 0 butter. |

| Project Name: Drinking Water Filling Machine | ||||||||

| Model | XGF8-8-3 | XGF14-12-5 | XGF16-16-5 | XGF24-24-8 | XGF32-32-8 | XGF40-40-10 | XGF50-50-15 | |

| Washing Nos | 8 | 14 | 16 | 24 | 32 | 40 | 50 | |

| Filling Nos | 8 | 12 | 16 | 24 | 32 | 40 | 50 | |

| Capping Nos | 3 | 5 | 5 | 8 | 8 | 10 | 15 | |

| Capacity(BPH) | 2000 | 5500 | 8000 | 12000 | 15000 | 18000 | 24000 | |

| Suitable bottle and cap | PET circular or square with screw cap | |||||||

| Bottle Volume | 150ml to 2.5Ltr (Customized) | |||||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||||

| Bottle heighter | 160-320mm | |||||||

| Compress air pressure(Mpa) | 0.3-0.4Mpa | |||||||

| Washing medium | Aspetic water | |||||||

| Rinsing pressure(Mpa) | >0.06Mpa<0.2Mpa | |||||||

| Filling temperature | Room temperature | |||||||

| Filling theory | By gravity | |||||||

| Total powder | 1.5KW | 2KW | 2.2KW | 2.2KW | 3KW | 7.5KW | 7.5KW | |

| Dimension (meter) | 2*1.5*2.5 | 2.4*1.8*2.7 | 2.9*2.2*2.8 | 2.9*2.2*2.8 | 3.4*2.6*2.8 | 4.4*3.3*2.8 | 4.7*3.6*2.8 | |

| Weight | ||||||||

Configuration List

| No | Name | Brand |

| 1 | Main motor | ABB |

| 2 | Cap unscrambler motor | FEITUO(China) |

| 3 | Conveyor motor | FEITUO(China) |

| 4 | Rinsing pump | CNP (China) |

| 5 | Solenoid valve | FESTO |

| 6 | Cylinder | FESTO |

| 7 | Air-T contactor | FESTO |

| 8 | Pressure adjust valve | FESTO |

| 9 | Inverter | MITSUBISHI |

| 10 | Power switch | MIWE(TAIWAN) |

| 11 | Contactor | SIEMENS |

| 12 | Relay | MITSUBISHI |

| 13 | Transformer | MIWE(TAIWAN) |

| 14 | Approx switch | TURCK |

| 17 | PLC | MITSUBISHI |

| 18 | Touch screen | Pro-face |

| 19 | Air components | FESTO |

| 20 | AC Contactor | Schneider |

| 21 | Micro relay | MITSUBISHI |

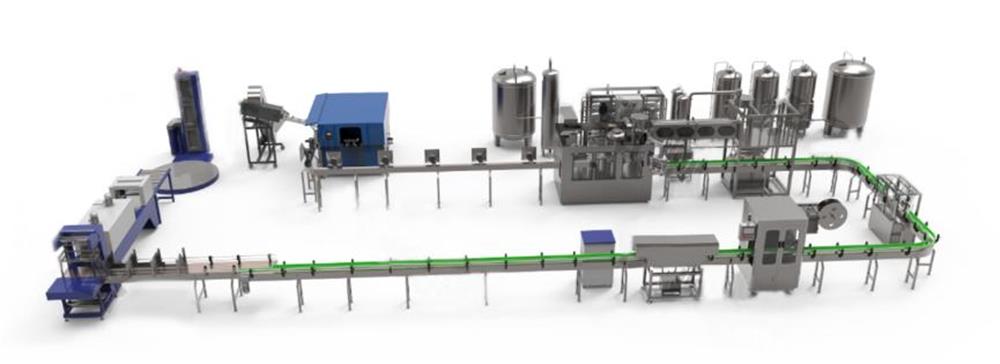

A To Z Layout

Why Choose Us

1. We are the direct manufacturer, we have been engaged in development and manufacturing of beverages and liquid food filling machines for more than 10 years, our plant area of 6000m2, with independent property rights. 2. We have a professional team for exporting, we can supply stable quality faster delivery and clearly communications. 3. We can make custom manufacturing, our technical team can design different size and products to meet your special requirements. 4. Without getting customer’s approve, we will not ship the equipment hastily, every equipment will be tested continuously 24 hours before loading, we will control every step strictly in the process of manufacture. 5. All of our equipment will have 12 months guarantee, and we will supply techinical servie all equipment life. 6. We will supply the spare parts fast and with cost price.